Company profile

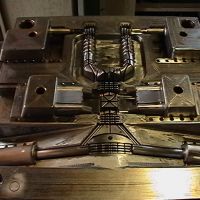

Thecnos was founded in 1988, starting to build molds for plastic materials for the footwear sector. Even without numerous tools and machinery, Thecnos' business grew up in the first ten years of activity, also covering the furniture sector.

Since the creation of the company Thecnos di Grigoletto Angelo, the main aim has been that of offering the customer continous co-operation for the construction of quality molds, rigorous timing in the work planning from the initial to intermediate and final stages of the work. During the decade of the 90s and subsequently with the advent of 2000 the company keeps on growing and introduces the CAD-CAM system thus entering the technical-industrial sector.

The customer portfolio is thus expanded and more and more companies in the most different sectors avail themselves of the co-operation of Thecnos di Grigoletto Angelo; today, the company works together with the best-known brands in medical, automotive, home appliances, sports, household articles and electronic plastic sectors.

And the company machinery fleet is also expanding: the acquisition of new machinery allows Thecnos di Grigoletto Angelo to produce steel and aluminum and die-casting molds, even of considerable size.

Currently the company has 10 employees: 2 CAD specialists (for design) 2 CAM sources for n. 6 CNC machines, 2 workers for tooling and 2 workers for the finishing and assembly.

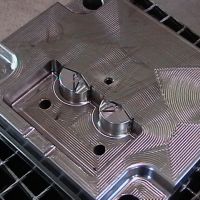

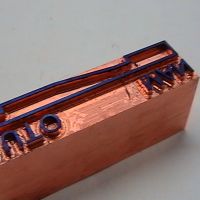

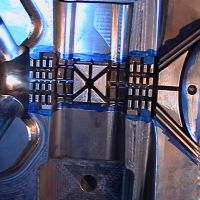

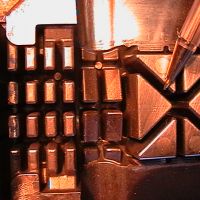

The careful production process begins with the analysis of a 3D project of the part to be built, the subsequent scrupulous design of the mold, the purchase of building materials and the CNC machining. We then move on to drilling, erosion, dimensional control of the pieces obtained, assembly, polishing, photoengraving and sandblasting up to the testing phase. The customer will be involved in the testing process for the fine-tuning of the product, for a possible optimisation of the mold and of the part until perfection is achieved.

A strong specialization obtained over the years, combined with constant updating and staff training have allowed the achievement of very high quality standards.

The company mission has always been that to fully satisfy the customer in order to create and maintain a relationship of growth and evolution that lasts over time.

Processing

With a constantly updating machinery, we cover all operational needs to obtain the maximum performance of both our engineers and the molds we produce.

Our engineering department, while assisting the internal production, constantly stand by the customer and can support them both in the R&D phase and in the customization constructive phase.

- Macchina CNC "Famup/Sertek"

- Elettroerosione a tuffo

- Trapani a bandiera

- Frese manuali

- Saldatura "Tig/Laser" SISMA

- Macchina CNC 5 Assi

- Dim. max. Stampi 1400x900x1000

- Peso max. 50 quintali

Eine Idee oder ein Projekt?

Request

Contatti.

Adresse

Via zona industriale 15

35020, Vigorovea di Sant'Angelo di Piove di Sacco, Padova

Tel. 049.9790719

Fax. 049.9794371

This email address is being protected from spambots. You need JavaScript enabled to view it.

Thecnos Stampi

Strada zona industriale 15

Vigorovea di San Angelo di Piove (Padova)